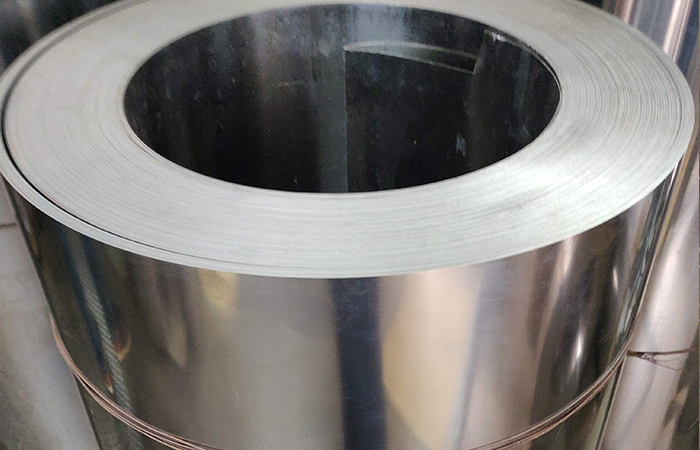

Steel alloys are the most commonly used spring materials. The most popular alloys include high-carbon (such as the music wire used for guitar strings), oil-tempered low-carbon, chrome silicon, chrome vanadium, and stainless steel. The term yield strength refers to a material’s ability to endure significant bending or twisting and return to its original shape without deforming. Spring steel stock alloys typically include silicone in their composition and are hardened and cold rolled after casting to improve yield strength. Spring steel products are generally either cold drawn as wire or punched from flat stock. Typical uses include saw blades, tape measures, helical springs, and vehicle suspension elements.

Spring steel alloys feature the unique characteristic of being able to withstand considerable twisting or bending forces without any distortion. Products made from these steel alloys can be bent, compressed, extended, or twisted continuously, and they will return to their original shape without suffering any deformation. This characteristic is defined as high yield strength and is the result of the specific composition and hardening of the steel alloy. Spring steels are medium-to-high carbon content alloys generally featuring a carbon content of 0.5 to 1.0 percent. The other alloy additives typically include manganese and silicone with silicone being the key component in high yield strengths.

Spring steel has many unique properties that make it ideal for producing springs and other similar components, including:

As a general-use steel, spring steel has a wide range of commercial applications. You can find it in just about any piece of manufacturing equipment, including:

Clips & fasteners — With high-strength and good fatigue resistance, spring steel is ideal for creating clips and fasteners that hold things together.

Springs — From everyday machinery to vehicular parts, spring steel is most commonly used to create coil springs, compression springs, torsion springs, and leaf springs.

Medical equipment — Spring steel is often used to create medical instruments, like surgical tools and orthodontic appliances.

Machinery — Spring steel is used for manufacturing machinery and equipment, from lawnmowers and aircrafts to conveyers and pumps.

Hand tools — With its high strength, spring steel is perfect for producing strong, durable tools like pliers, wrenches, and scissors.

+91 9820481876

022-23079961

foremostalloy@gmail.com

2/13, Pais, Street, Next to Jyoti Furniture, Byculla, Mumbai - 400011

Incorporated in the year 1982, we, Foremost Alloy Steel Co. is renowned manufacturers, trader, wholesaler, retailer, importer and exporters of a wide assortment of Stainless Steel Products, Titanium Products, Aluminium Alloys Products, Metal Products, Phosphor Bronze Products, Aluminium Bronze Product and many more.