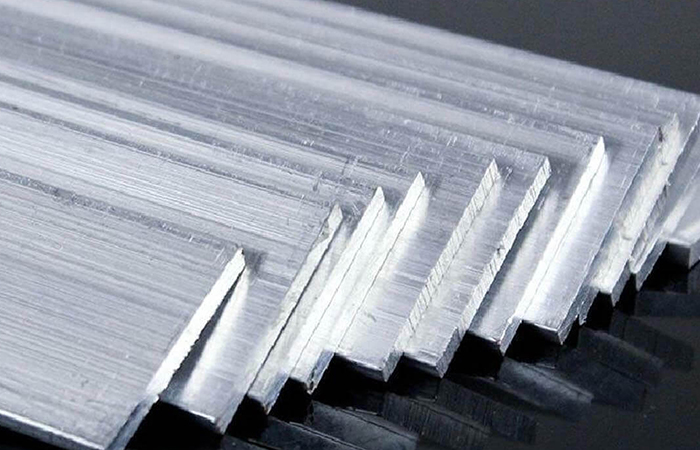

Aluminum is one of the most important representatives for metallic lightweight materials. It is extremely easy to process, can be recycled almost indefinitely, and is available in almost unlimited quantities. The differences in aluminum alloys mainly arise from their formability, strength, weather resistance and weldability. Aluminum alloys contain numerous alloying elements that influence the material’s properties. The main alloying elements used include silicon, magnesium, manganese, copper and zinc, among others. E.g. They increase strength or improve corrosion resistance using a process known as solid solution strengthening. Furthermore, special alloying elements such as bismuth or lead are used to improve chip breaking during milling, drilling and turning, or silver to prevent sparking.

Not all aluminum is created equal. Wrought aluminum alloys are usually designated by a four-digit number system established by the Aluminum Association instead of their material number. Here, the first digit indicates the main alloying element and consequently, the alloy group. The remaining digits are more or less counting numbers, assigned chronologically or following existing alloys.

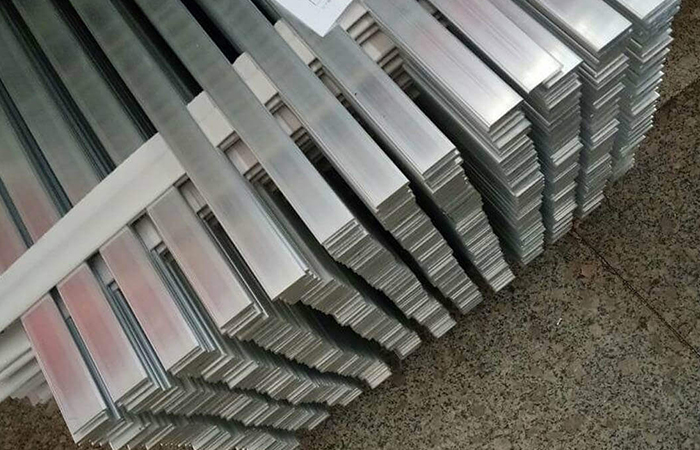

Aluminum is extremely easy to process and is available in almost unlimited quantities due to the recyclability of the end-of-life material. With optimal properties for technical requirements, aluminum is very easy to form and is particularly resistant to corrosion, has high strength, a large load capacity while offering extreme flexibility and a low weight.

+91 9820481876

022-23079961

foremostalloy@gmail.com

2/13, Pais, Street, Next to Jyoti Furniture, Byculla, Mumbai - 400011

Incorporated in the year 1982, we, Foremost Alloy Steel Co. is renowned manufacturers, trader, wholesaler, retailer, importer and exporters of a wide assortment of Stainless Steel Products, Titanium Products, Aluminium Alloys Products, Metal Products, Phosphor Bronze Products, Aluminium Bronze Product and many more.